Operational Technology (OT) equipment has become fundamental for businesses across a range of industries, transforming traditional processes into data-driven practices. As global competition intensifies and demands for efficiency rise, understanding the roles and functionality of OT equipment is vital for business owners. From industrial control systems to sensors that monitor real-time metrics, this article covers the core functionalities and diverse applications of OT equipment, highlights real-world scenarios across various sectors, addresses security challenges, and discusses emerging trends that shape the future of OT technology.

Sensing, Deciding, Acting: The Core Roles and Impact of OT Equipment

Operational technology (OT) equipment sits at a precise and consequential point in modern industry. It connects the physical world with digital control, forming a closed loop where sensing feeds decision making and actions shape reality. This triad—sense, decide, act—underpins the safety, reliability, and efficiency of critical systems across manufacturing, energy, transportation, and public infrastructure.

The sensing layer gathers data from sensors that measure temperature, pressure, vibration, flow, level, and other physical parameters. Accurate sensing is foundational; it determines whether downstream decisions reflect actual conditions. The decision layer, implemented in PLCs, DCS, and SCADA systems, translates measurements into timely, deterministic commands. The execution layer then moves actuators, valves, motors, and robots to carry out those commands in a controlled, safe manner.

Across sectors, OT equipment interlocks with IT ecosystems to enable analytics, remote monitoring, and optimization. This convergence brings opportunities for improved performance and resilience but also expands the attack surface, highlighting the need for segmentation, strong access controls, and continuous security monitoring. As OT advances toward edge intelligence and digital twins, operators gain deeper visibility and predictive capability, while maintaining the essential guarantees of real-time determinism and physical safety.

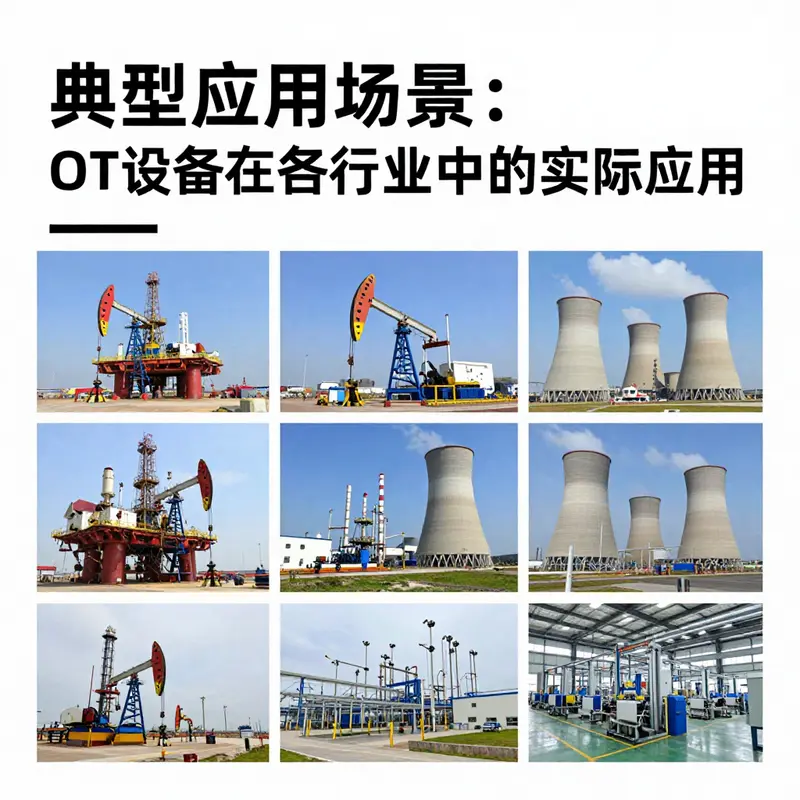

数字脉冲在工业中的现实应用:OT设备贯穿制造、能源与环境的协同控制

外部参考链接,供进一步探讨相关应用案例与理论基础: https://www.baidu.com/s?wd=%E7%B2%BE%E7%82%BC%E8%AE%BE%E5%A4%87%E5%9C%A8%E4%B8%8D%E5%90%8C%E8%A1%8C%E4%B8%9A%E7%9A%84%E5%BA%94%E7%94%A8%E6%A1%88%E4%BE%8B%E5%88%86%E4%BA%AB

守护工业之心:OT设备网络安全的综合防护路径

在数字化转型的浪潮中,运营技术(OT)与信息技术(IT)的边界日益模糊。工业现场的传感器、可编程逻辑控制器(PLC)、分布式控制系统(DCS)以及执行机构,如阀门与泵,正通过企业网络、远程运维通道乃至云端服务实现数字化连接。这一趋势带来了前所未有的协同效益——更高的可视性、更精准的调度以及更灵活的资源调配——同时也暴露出新的安全挑战。OT设备往往承载关键的生产任务,任何干扰都可能带来生产中断、安全风险甚至环境事故。然而,传统的OT体系曾以物理隔离和专用协议著称,如今的互联互通使得恶意软件、勒索攻击、内部威胁以及供应链风险更容易侵入。企业若要在保持高可靠性与安全性的前提下推进数字化,就需要构建一套全面、层次分明且可落地的防护体系。

现实世界的教训清晰而沉重:以往的补丁策略在许多旧型OT设备上并不可行,因为停机时间的代价极高,设备往往在苛刻的实时约束下工作,升级或重启可能引发生产波动甚至安全隐患。这种背景下,零日漏洞或配置错误就会成为长期存在的隐患点。研究显示,越来越多的工业环境遭遇攻击,且攻击路径多来自IT环境进入OT网络。这一现象提醒我们,OT安全不是单点防护的游戏,而是一个需要在全局范围内实现资产可视化、行为基线建立、以及持续自适应防御的系统工程。

其次是网络分段与边界控制。OT网络的分段不仅仅是“把设备分成若干块”,而是在关键节点布置专用防火墙、交换机策略与微分段策略,确保横向移动在入侵初期就被阻断。有效的分段使攻击者即使突破外围也难以进入至关键生产控制层,从而将影响范围局限在最小范围内。这一理念与传统IT网络的边界防护有所不同:在OT环境中,分段的实现需要考虑实时性、确定性和对关键控制回路的不中断支持。因此,防火墙策略必须与工业协议的时序、报文格式、以及控制系统的安全需求相兼容,避免因误报或性能下降而影响生产可靠性。

在访问控制方面,零信任与最小权限原则被公认为应对OT网络复杂性的重要路径。无论是内部用户、维修工程师,还是远程运维服务提供商,所有访问请求都应经过多因素身份认证(MFA),并且仅给予完成工作所必需的最低权限。OT系统往往对时间和状态的要求极高,因此访问管理还需要支持基于任务的会话控制、严格的会话时长、以及对会话行为的实时监控。对设备本身,抛开传统的口令防护,应该引入设备级的身份认证和任务级授权,减少“隐形授权”带来的风险。零信任的实现并非一蹴而就,它要求跨 IT/OT 的治理结构、统一的策略框架,以及能够跨域执行的自动化响应能力。

持续监控与威胁防护是防线中的关键翼。工业协议如Modbus、DNP3、OPC UA等,具备特定的语义与行为特征,往往需要具备行业专业知识的威胁检测能力来识别异常。仅靠通用的网络入侵检测系统,往往无法捕捉对生产安全至关重要的异常行为。于是,越来越多的企业开始部署“ICS-aware”的监控系统,能够理解工业协议的合法通信模式,对未经授权的控制指令、异常的数据流、以及对关键设备的非计划访问发出告警。在无法立即打补丁的老旧设备上,虚拟补丁成为一种现实的防护手段,通过对已知漏洞的异常流量建立规则,阻断恶意利用的路径,减少实际风险。

数据保护与通信的安全同样不可忽视。虽然许多OT设备对加密、身份验证等现代安全特性支持有限,但可以通过加密网关、受控的远程访问通道,以及对传输数据进行完整性校验来提升整体防护水平。对日志、报警与事件的集中管理,也应当遵循一致的时间同步与标准化格式,确保事件在不同系统间能够被关联、溯源与分析。

在选择解决方案时,企业应优先考虑那些能够横跨IT与OT、覆盖端到端安全需求的综合平台,并确保其符合国际标准与行业安全框架。IEC 62443-4-2等标准为OT系统的组件级安全提供了明确的要求,帮助企业在设计阶段就将身份、访问、加密、更新和容错等要素纳入考虑。更重要的是,选型并非仅看单一产品的强度,而是看整个安全框架的协同性与自动化能力。一个统一的安全平台可以将策略、日志、告警与响应流程集中化管理,降低运维复杂性,提高响应速度。

但任何安全体系都不能仅凭工具堆砌。治理层面的建设同样关键:建立资产审计与变更管理机制,确保每一次设备接入、每一次固件更新、及每一次网络拓扑调整都被记录和审核。供应链安全在OT环境中尤为重要,因为组件工序中的任何环节都可能成为攻击的入口。对供应商提供的软件与固件版本实行严格的版本控制、供货认证与回溯能力,确保组件来自可信源且更新可控。

将这些要素连成一个连贯的防线,企业可以建立一个主动、动态且具备韧性的安全态势。首先,清晰的资产清单与通信矩阵构成了防御的原点;其次,分段策略将攻击者的移动路径切断,保护关键控制回路;再次,访问控制与会话管理将人为错误与内部威胁降到最低;再者,持续监控与虚拟补丁为难以直接修补的设备提供临时护盾;最后,统一的安全平台和治理框架则保证策略在全网范围内的一致执行。所有这些要素共同作用,才能在OT与IT深度融合的现实中,降低风险、提升可靠性,并为企业在不断演化的工控生态中保留足够的弹性空间。

从更宏观的视角看,安全不能被视为一次性项目,而应是一种持续的能力。企业需要将网络安全嵌入到生产计划、维护日程和应急演练之中,形成一个“安全即生产力”的循环闭环。人员培训在此尤为重要,操作员、维护人员与安全团队之间的沟通要畅通无阻,了解哪些行为可能带来风险、哪些变更需要提前评估,以及在异常情况下应如何协同响应。通过培养这种安全意识,组织才能在复杂的生产环境中保持敏捷,同时降低因误操作、系统升级或远端访问带来的潜在风险。

实践层面的路径并非一成不变。企业在推进时,应以分阶段、渐进式的方法来实现目标:第一阶段聚焦可见性与资产清单,建立基础监控和告警;第二阶段完善分段与访问控制,部署ICS-aware威胁检测与虚拟补丁;第三阶段推动标准化的治理框架、供应链安全与跨域协同,确保策略可持续执行;第四阶段则在新场景中持续优化,如引入更智能的行为分析、自动化响应与自适应防御。每一步都需要与生产目标保持一致,避免因安全投入而牺牲产能与可用性。

对于企业来说,面向未来的OT安全意味着更高的自适应性和更强的自我修复能力。随着工业物联网、云端分析和边缘计算的兴起,安全架构的边界将继续扩展,但核心原则不会改变:清晰的可见性、严格的分段、无条件的访问控制、持续的威胁监控,以及以标准为基底的治理。只有这样,OT设备才能在高强度生产环境中,稳健运行并持续提供价值。

外部资源可以为企业提供更广阔的视角与实践经验。关于工业网络安全的进一步分析与实践指南,读者可以参考相关的行业资料与外部研究,以获取最新的安全对策与案例参考。外部链接如下,供深入学习之用: https://www.fortinet.com/zh-hant/solutions/industrial-network-security

Future Trajectories of OT Equipment: Evolution, Integration, and the Promise of Smart Industrial Control

OT equipment is evolving from isolated devices into an integrated, data-driven fabric that binds sensing, actuation, and analytics into a unified operational intelligence layer. Rather than operating as discrete, proprietary islands, modern OT assets are being designed for open interoperability, programmable interfaces, and cross-domain collaboration with IT systems. Standards-based interfaces and models—such as ISA-95 concepts—are turning into the practical grammar by which plants and enterprise systems speak the same language. The result is a digital thread from design to manufacturing and service, where devices are reusable, configurable components whose value comes from interoperability and data enrichment rather than single-process control alone.

The second pillar is a resilient, intelligent network that binds OT to IT with fidelity and agility. Networks are reimagined as dynamic service fabrics that allocate bandwidth and latency in real time, provide end-to-end visibility, and support edge-to-cloud deployments. This enables predictable control loop performance, reduces data silos, and allows analytics and optimization to run closer to the data source. The architecture supports hybrid computing models, governance, and security by design, balancing openness with safety and accountability.

A third thread is AIoT, where AI and OT converge to enable proactive maintenance, adaptive control, and autonomous optimization. Predictive maintenance, digital twins, and continuous feedback loops let OT devices sense, interpret, and react within safety and governance boundaries. Data-driven models feed control strategies, producing faster experimentation and more resilient operations. OT assets evolve from passive instruments to active participants in optimization, capable of cross-domain collaboration with ERP, MES, and other enterprise platforms.

Beyond technology, these trends reshape business models and governance for OT. Service-oriented approaches, asset performance metrics, and supply-chain transparency become the norm, while cybersecurity remains foundational. The mature OT ecosystem embraces standardized data, modular architectures, and auditable operations to manage risk, resilience, and value creation across the enterprise.

In summary, the future OT landscape is a coordinated ascent of systems, standards, and services that expand interoperability, enable intelligent decision making, and align shop-floor action with corporate objectives. The payoff is improved reliability, adaptability, and efficiency across manufacturing networks, with data-driven governance ensuring safety, security, and sustainable innovation.

Final thoughts

Proficiently integrating OT equipment into your business strategy offers not only immediate operational efficiencies but also positions your organization for future growth amidst evolving technologies. As you navigate the complexities of industrial automation, consider the impact of OT equipment on your bottom line and invest in robust security measures to safeguard against potential vulnerabilities. Embracing these advancements will empower you to harness data for better decision-making and achieve a competitive edge in your market.